Technology

Joining manufacturing processes

By stampling the initial contact of the joining partners is generated by heat and pressure. The top of the tool is led through the surface by a hot air flow within the thermoplastic area. During the further procedure, flow processes occur and sliding (free mobility, deformability) of the molecular chains take place among each other.

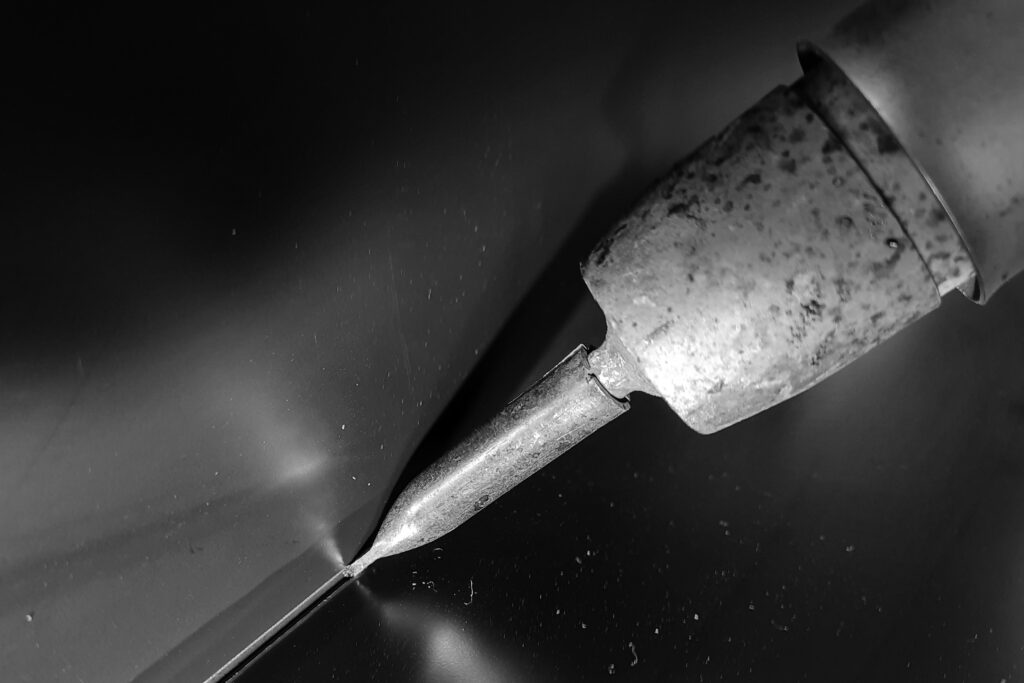

The hot gas welding creates a permanent joint between the workpieces. The welding wire is forced through the drawing nozzle into the area to be joined.

By the hot gas extrusion welding the final connection of the joining partners is achieved. The extruder draws in the welding wire, which is brought to the appropriate temperature in the hot gas unit and then applied as a plasticized compound through the welding shoe.

The heating element butt welding of workpieces is used, for example, to join pipes at an angle. Heat brings the components to the processable state where they are then joined under pressure.

Cutting manufacturing processes

The sawing is usually the first production step and is for example intended to produce plates in the correct size for further processing.

By the deburring on the edges of the workpiece, the burr, created in the previous step, is removed. In this way, the impairment from the connection of the stampling process can be avoided.

By drilling mainly holes are made, into which for example threads can subsequently be cut or nozzles welded in.

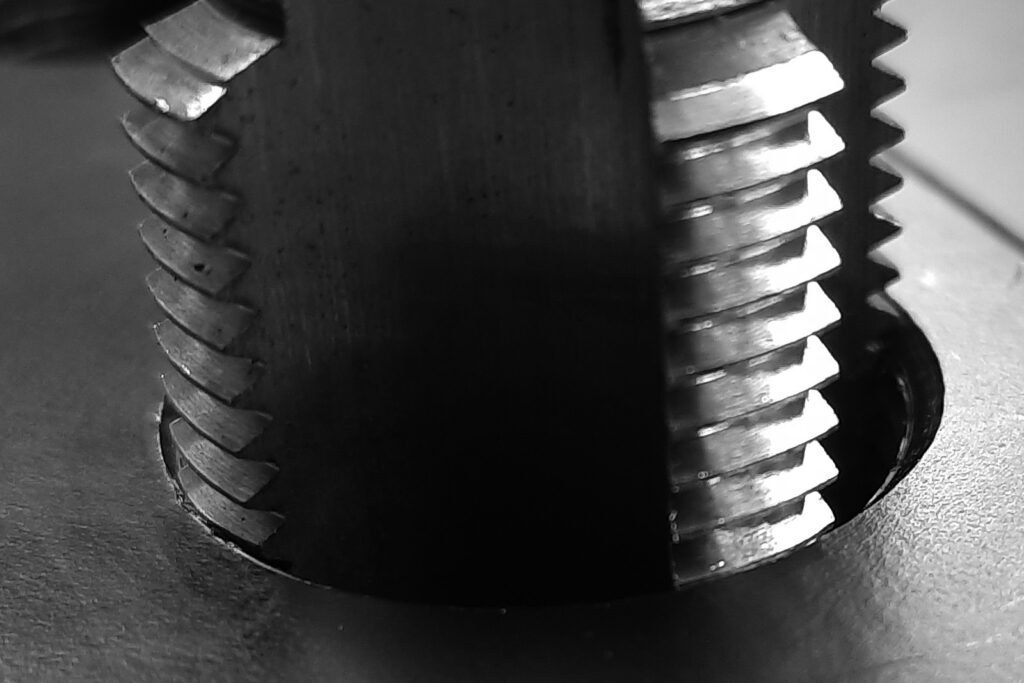

The thread cutting is mainly done to attach grommets which can be used as hose connections.

By the cylindrical deburring of drilled holes, the burr, which has been generated in the previous step, is removed so that components can be better fastened onto them.